Taylor Hobson’s ongoing developments support automation, data exchange and process control in manufacturing environments.

Smart manufacturing - supported by Taylor Hobson

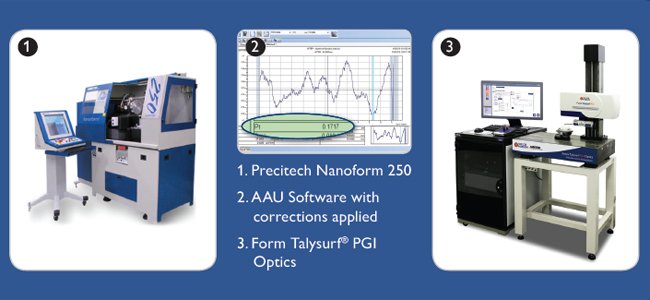

Taylor Hobson and Precitech have developed software that enables the machine tool and metrology instrument to communicate with each other. This enables automatic correction of the X-offset and tool radius errors, providing a significant reduction in set-up time and improved process performance.

(1. Precitech Nanoform 250 2. AAU Software with corrections applied 3. Form Talysurf® PGI Optics )

Taylor Hobson can now offer an automated robot load/unload system to change parts quickly, which reduces cycle time and increases productivity. The new Talyrond® 500 HS uses an automated rotary stage to enable the measurement of multiple components in a single set-up. The new Form Talysurf® CNC system delivers fully automated surface finish, form and contour at the touch of a button.

(4.Talyrond® 500 HS, 5.Multi-part measurement, 6. Form Talysurf® with UR3 robotic arm)

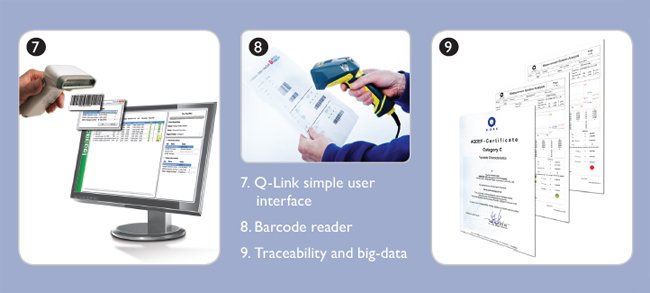

Taylor Hobson has developed software specifically for production environments. Q-Link provides direct communication with SPC software which delivers feedback to your manufacturing process.

Q-Link is QDAS accredited and offers automatic R&R studies, instant screen report summary with pass/fail results delivering long-term traceability and big-data-driven quality control.

(7. Q-Link simple user interface, 8.Barcode reader, 9. Traceability and big-data)